Hot Product

Refractory Knowledge

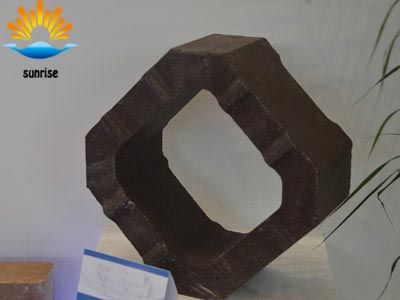

Types And Properties Of Magnesia Chrome Refractories

Date:2016-06-14 19:00 From:Zhengzhou Sunrise Refractory Author:admin

Magnesia chrome refractories used in cement kilns can be divided into 3 types: common brick, directly bonded brick and low chrome brick.

(1) Common magnesia chrome brick

It is made of mid-grade or lower magnesia sand and low-grade chrome ore and sintered at low temperature. Since it has a high content of silicate phase and a low content of secondary spinels, periclase is surronded with silicate glass phase. Due to this, it has poor high temperature resistance, corrosion resistance and thermal shock resistance.

Low-melting-point silicate phase is a contineous phase, while the high-melting-point phases are like islands floating in the low-melting-point silicate phase. At high temperature, the softening of the low-melting-point phase will affect the properties of refractories. Therefore, the softening temperature under load, hot strength, volume stability are significantly poorer than these of other magnesia chrome refractories.

Glass phase is the weak point of refractories and the channel through which the impuries invade into the bricks. Glass phase is brittle. When there are too many low-melting-point substances, refractories will be ceramized at high temperature. Cracks will fastly spread along the glass phase, which makes the refractory have bad thermal shock resistance.

Common magnesia chrome brick is cheap , but its properties are not very good, so it it mainly used in the firing zone of small and medium cement rotary kilns.

(2) Directly bonded magnesia chrome brick

It is made of high-grade magnesia and chrome ore by special precesses such as improving the firing temperature. Since it have a low content of silicate phase and a high content of secondary spinels, silicate phase becomes islands, while there are direct bonds such as periclase-periclase and periclase-chromite. Therefore, the direct bonds give the brick high temperature resistance, corrosion resistance and thermal shock resistance.

During the firing process, chrome diffuses into magnesia sand from chromite and forms periclase solid solution. When the temperature decreases, MgO•R2O3 seeds out from oversaturated periclase solid solution and forms secondary spinels. Since chrome changes the properties of periclase, periclase is difficult to be wet by silicate phase, which promopts the formation of direct bonds of periclase- periclase and periclase- magnesia chrome spinel.

Directly bonded magnesia chrome brick is relatively expansive, but it has good high temperature resistance, corrosion resistance, thermal shock resistance and skin hanging properties, so it is suitable to the firing zone of various cement rotary kilns.

(3) Low chrome magnesia chrome brick

In order o reduce the pollution of Cr6+, low chrome magnesia chrome brick is developed. It is made of high-iron magnesia sand and chromite. A part of magnesia spinel is replaced by magnesia iron spinel. At high temperature, Fe2O3 in the high-iron magnesia sand dissolves in periclase. During the cooling process, MgO•Fe2O3 seeds out from periclase and forms pit-like magnesia iron spinel scattered in periclase.

Magnesia iron spinel has a particle size between 1-3μm and is wrapped with periclase. Therefore, iron oxide has little effect on the high temperature properties of refractories. In other words, the key of its process is to replace a part of magnesia chrome spinel with magnesia iron spinel. Fulfill the benefitial effect of Fe2O3 and Cr2O3 by limiting the harmful effect of Fe2O3 to maintain the properties and service life of refractories.

Its physical property is a little poorer than that of directly bonded magnesia chrome brick, because its firing temperature is lower, while their service life are well matched.

Inquiry:

If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, a representative will contact you within one business day. We guarantee that your information will not be divulged to the third party.