Hot Product

Refractory Knowledge

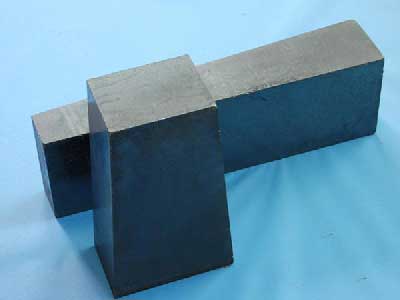

One of the most commonly used raw materials for magnesia refractory——Sintered magnesia

Date:2019-10-31 15:59 From:Zhengzhou Sunrise Refractory Author:admin

Sintered magnesia is usually obtained by calcining a magnesite, a brucite, and magnesium hydroxide extracted from seawater or brine using a rotary kiln and a shaft kiln.

Light burnt magnesia is magnesia obtained after magnesite is calcined at about 700~1100 °C, also called light burnt magnesia. Light burnt magnesium powder is light and soft, has a porous structure, density of 3.07-3.22g/cm3, and the magnesia grain is small (<3μm), and the reaction activity is large, and solid phase reaction and sintering are prone to occur. A product having a high bulk density and a low porosity is obtained by magnesia or light burnt magnesia sufficiently sintered at 1450-1900 ° C, and is called dead burned magnesia, also called calcined magnesia and calcined magnesia.

The dead burned magnesia is very dense, and the density fluctuates between 2.95-3.65g/cm3 depending on the impurity content, phase composition and structure. The magnesia produced by the production of magnesia obtained from seawater is called seawater magnesia. It is obtained by calcination decomposition and high-temperature sintering by using Mg(OH)2 or bischofite obtained by precipitation of Mg2+ in seawater. . The advantage of seawater magnesia is that the seawater is inexhaustible, and the product has high purity, MgO content of more than 95%, easy adjustment of chemical composition, and density of 3.30-3.49g/cm3.

The dead burned magnesia is very dense, and the density fluctuates between 2.95-3.65g/cm3 depending on the impurity content, phase composition and structure. The magnesia produced by the production of magnesia obtained from seawater is called seawater magnesia. It is obtained by calcination decomposition and high-temperature sintering by using Mg(OH)2 or bischofite obtained by precipitation of Mg2+ in seawater. . The advantage of seawater magnesia is that the seawater is inexhaustible, and the product has high purity, MgO content of more than 95%, easy adjustment of chemical composition, and density of 3.30-3.49g/cm3.

The determination of the degree of sintering of magnesia is usually measured by body density, hydration performance, and shrinkage of reburning line. According to the purity of magnesia, magnesia can be divided into high-grade (high-purity) magnesia with MgO content greater than 97%, mid-range magnesia 95%~96%, and ordinary magnesia (brick masonite) with MgO content less than 95%. Mid-range magnesia is an indispensable magnesia variety in magnesium products. It is applied to mid-range magnesia bricks, magnesium composite spinel bricks, direct-bonded magnesia bricks and some magnesia-shaped refractory materials. The MgO content in high-purity magnesia is not less than 97%, and can be used as a main raw material for directly bonding magnesium brick and magnesium composite spinel brick.

Inquiry:

If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, a representative will contact you within one business day. We guarantee that your information will not be divulged to the third party.