Hot Product

Refractory Knowledge

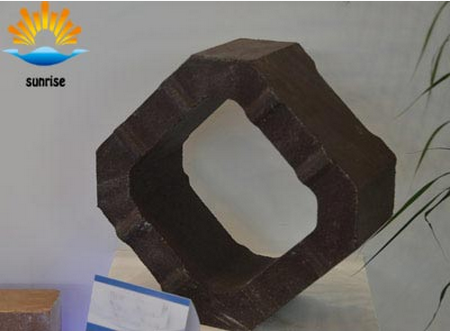

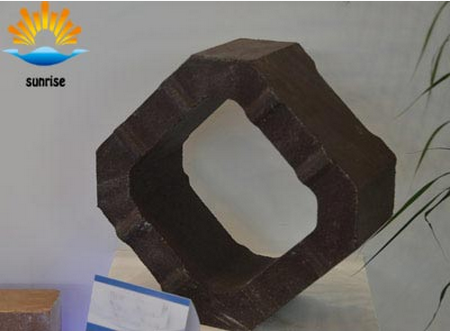

The raw materials of Refractory Brick and firing methods

Date:2016-09-02 18:27 From:Zhengzhou Sunrise Refractory Author:admin

Refractory brick has a variety of raw materials, the composition is mainly divide with the six categories: earth, stone, sand, ore, powder and other.

1. Earth: aluminum earth, kaolin earth, clay, diatomaceous earth.

2. Stone: fluorite, kyanite, andalusite, forsterite, vermiculite, mullite, pyrophyllite, chlorite, dolomite, sillimanite, magnesium aluminate spinel, silica.

3. Sand: ceramic sand, zircon sand, quartz sand, magnesia snad.

4. Ore: chrome ore.

5. Powder: metal aluminium powder, silicon powder and silicon metal powder.

6. Other: Asphalt, graphite, phenolic resin, perlite, floating bead, corundum, sulfuric acid silicon, silicon carbide, soluble glass, silica sol, boron carbide, calcium aluminate cement,

nitride materials, shale ceramsite, alumina, alumina sol, zirconium oxide, etc.

The firing stages of refractory brick:

1. At room temperature to 200 ℃, the temperature should not be too fast, in case of refractory brick body cracking, in the tunnel kiln firing, the former 4 parking temperature should

not exceed 200 ℃.

2. 200 ~ 900℃: the temperature should speed up in the stage, for the organic matter content in the refractory brick and impurities of chemical reactions to conduct. During the

period of 600 ~ 900 ℃, should stay stronger oxidation atmosphere in furnace, avoid the "black heart" refractory waste.

3. 900℃ to the highest firing temperature: in the high temperature stage, should be smooth temperature and steady, continue to maintain the oxidizing atmosphere, make the

refractory brick body heated evenly, also need to prevent cracking of refractory brick. Due to above 1100 ℃ high temperature, sintering shrinkage is very strong, shrinkage rate

reaches 2-5%, so keep the gentle temperature gradient, eliminate internal stress is very important.

4. Cooling stage: according to the character changes of refractory products in the cooling section, the temperature should be fast cooling above of 800 ~ 1000 ℃ high temperature

stage, under 800 ℃, should slow cooling rate, in fact, in the actual production, the cooling speed of actual use will not cause cold cracking risk to refractory products.

1. Earth: aluminum earth, kaolin earth, clay, diatomaceous earth.

2. Stone: fluorite, kyanite, andalusite, forsterite, vermiculite, mullite, pyrophyllite, chlorite, dolomite, sillimanite, magnesium aluminate spinel, silica.

3. Sand: ceramic sand, zircon sand, quartz sand, magnesia snad.

4. Ore: chrome ore.

5. Powder: metal aluminium powder, silicon powder and silicon metal powder.

6. Other: Asphalt, graphite, phenolic resin, perlite, floating bead, corundum, sulfuric acid silicon, silicon carbide, soluble glass, silica sol, boron carbide, calcium aluminate cement,

nitride materials, shale ceramsite, alumina, alumina sol, zirconium oxide, etc.

The firing stages of refractory brick:

1. At room temperature to 200 ℃, the temperature should not be too fast, in case of refractory brick body cracking, in the tunnel kiln firing, the former 4 parking temperature should

not exceed 200 ℃.

2. 200 ~ 900℃: the temperature should speed up in the stage, for the organic matter content in the refractory brick and impurities of chemical reactions to conduct. During the

period of 600 ~ 900 ℃, should stay stronger oxidation atmosphere in furnace, avoid the "black heart" refractory waste.

3. 900℃ to the highest firing temperature: in the high temperature stage, should be smooth temperature and steady, continue to maintain the oxidizing atmosphere, make the

refractory brick body heated evenly, also need to prevent cracking of refractory brick. Due to above 1100 ℃ high temperature, sintering shrinkage is very strong, shrinkage rate

reaches 2-5%, so keep the gentle temperature gradient, eliminate internal stress is very important.

4. Cooling stage: according to the character changes of refractory products in the cooling section, the temperature should be fast cooling above of 800 ~ 1000 ℃ high temperature

stage, under 800 ℃, should slow cooling rate, in fact, in the actual production, the cooling speed of actual use will not cause cold cracking risk to refractory products.

Inquiry:

If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, a representative will contact you within one business day. We guarantee that your information will not be divulged to the third party.