Hot Product

Refractory Knowledge

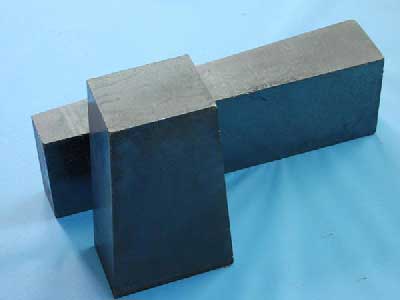

High Quality Sunrise Refractory Magnesia Carbon Brick

Date:2018-12-07 15:32 From:Zhengzhou Sunrise Refractory Author:admin

Sunrise refractory magnesia carbon brick is a high melting point basic oxide magnesium oxide (melting point 2800 ° C) and a high melting point carbon material which is difficult to be infiltrated by slag as a raw material, and various non-oxide additives are added. A non-burning carbon composite refractory material combined with a carbonaceous binder. Magnesia carbon bricks are mainly used for the lining of converters, AC arc furnaces, DC arc furnaces, and slag lines of ladle.

As a composite refractory material, magnesia carbon brick effectively utilizes the strong slag corrosion resistance of magnesia and the high thermal conductivity and low expansion of carbon, which compensates for the biggest disadvantage of poor flaking resistance of magnesia.

Our Sunrise refractory magnesia carbon bricks have many features, such as, good high temperature resistance, strong slag resistance, good thermal shock resistance and low temperature creep.

Then, please allows me to introduce our preparation process of magnesia carbon bricks:

The conventional magnesia carbon bricks produced by the synthetic tar binder in accordance with the cold mixing process are hardened during the tar damage process and obtain the necessary strength, thus forming an isotropic glassy carbon. Such carbon does not exhibit thermoplasticity, and the thermoplastic can eliminate a large amount of stress in a timely manner during baking or handling of the liner. The magnesia carbon brick produced by the asphalt binder has a high temperature plasticity due to the formation of an anisotropic graphitized coke structure during the carbonization of the asphalt.

The refractory material used in the early ladle slag line is directly combined with magnesia chrome brick, fused and then combined with high-quality alkaline brick such as magnesia chrome brick. After the MgO-C brick was successfully used on the converter, the MgO-C brick was also used in the refining ladle slag line, and good results were obtained. At present, China and Japan generally use resin-bonded MgO-C bricks with a carbon content of 12% to 20%, while in Europe, asphalt-bonded MgO-C bricks are used, and the carbon content is generally about 10%.

Inquiry:

If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, a representative will contact you within one business day. We guarantee that your information will not be divulged to the third party.