Hot Product

Refractory Knowledge

Magnesium refractory castable physical properties

Date:2019-11-08 14:57 From:Zhengzhou Sunrise Refractory Author:admin

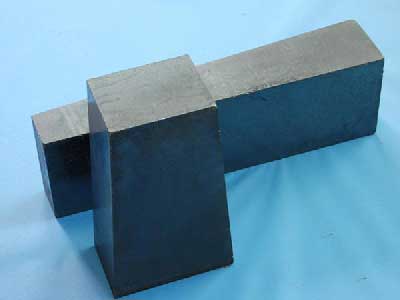

The magnesia refractory castable is a castable refractory material mainly composed of magnesium oxide (MgO). According to the material, it can be divided into: alkaline castables such as magnesia, magnesia, spinel, magnesia, magnesia and magnesia. Magnesia (permanite) refractory castables are prepared from fused magnesia or sintered magnesia aggregates and fine powders. Magnesia refractory castables combined with high-magnesium cement have high purity and low rate of change after burning. The load softening temperature is high, but as the heat treatment temperature increases, especially between 400 and 1200 °C, the magnesium hydroxide formed by the hydration of magnesia dehydrates and loses the cementation effect. The combination of refractory aggregate and powder is loose. Peeling off.

The water glass combined magnesia refractory castable has the advantages of high strength, alkali resistance and strong erosion ability of sodium salt melt. However, due to the use of water glass as a binder to bring in a large amount of Na2O (or K2O) and SiO2, the fire resistance, load softening temperature and the like of the magnesia refractory castable are greatly reduced, thereby limiting the maximum of the water glass bonded castable. Operating temperature.

The polyphosphate-bonded magnesia refractory castable has the advantages of high post-burning strength, small decrease in strength with heat treatment temperature, high softening temperature and good thermal shock resistance, but at high temperatures (above 1400 ° C). Due to the large amount of P2O3 volatilization, the magnesia castable strength is Jiangdu. In general, magnesium castables use sodium polyphosphate as a binder. Commonly used are sodium tripolyphosphate, sodium hexametaphosphate and the like. The degree of polymerization of polyphosphate and the content of P2O3 have a great influence on the strength of the castable. The castable strength is greatest when the average degree of polymerization of the polyphosphate is 24.

In addition, in order to increase the high temperature strength of the magnesia refractory castable, an appropriate amount of a calcium-containing material (such as calcium carbonate) is added to form a Na2O·2CaO·P2O5 phase which is high in aggregate strength and stable at a high temperature at a high temperature. However, it is difficult to overcome the problem of easy hydration of the magnesia refractory castable regardless of the use of the above-mentioned binders, and cracks are likely to occur during the drying process. Adding an appropriate amount of ultrafine silica powder can overcome the hydration problem.

Inquiry:

If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, a representative will contact you within one business day. We guarantee that your information will not be divulged to the third party.